Now it's spring 2025 and I am keen to

get the little red car back in shape for *this* year's

Microcar event!

Hope springs eternal.

I have, on hand now, the replacement transmission (thank you Gabi B for putting me in touch with the seller, and thank s to the seller, Sarha M's husband - whose name escapes me right now but I'll remember it!), and a new motor from EVWest, a NetGain Micro 880 paired with a HyPer-Drive X125 controller. It's a 100V, 250A combo capable of delivering 10 kW continuously (about 13hp which compares favorably with the output of the original two-cylinder, two-stroke 399cc motor).

And this represents another weight-loss step: This motor is 40 lbs. Less still than the 65 lbs of the shunt-wound from the last two iterations, and way less than 185-lb forklift motor from the professor's conversion.

I will also be using lithium battery modules from an Ioniq 5 battery pack. I think it will be ten modules in two strings of five. More on that later.

Note that I opted not to use a Golden Motor set-up. Great price, and good specs for continuous power output (about the same as the NetGain), but the torque was a relatively light 24 ft-lb compared to the 98 ft-lb of the NetGain though still 20% better than the 20 ft-lb of the original internal-combustion motor (at 2200 rpm).

Not that I am not going to have to be careful about torque; I have to protect the little transmission! As mentioned above, I'm on my first replacement already.

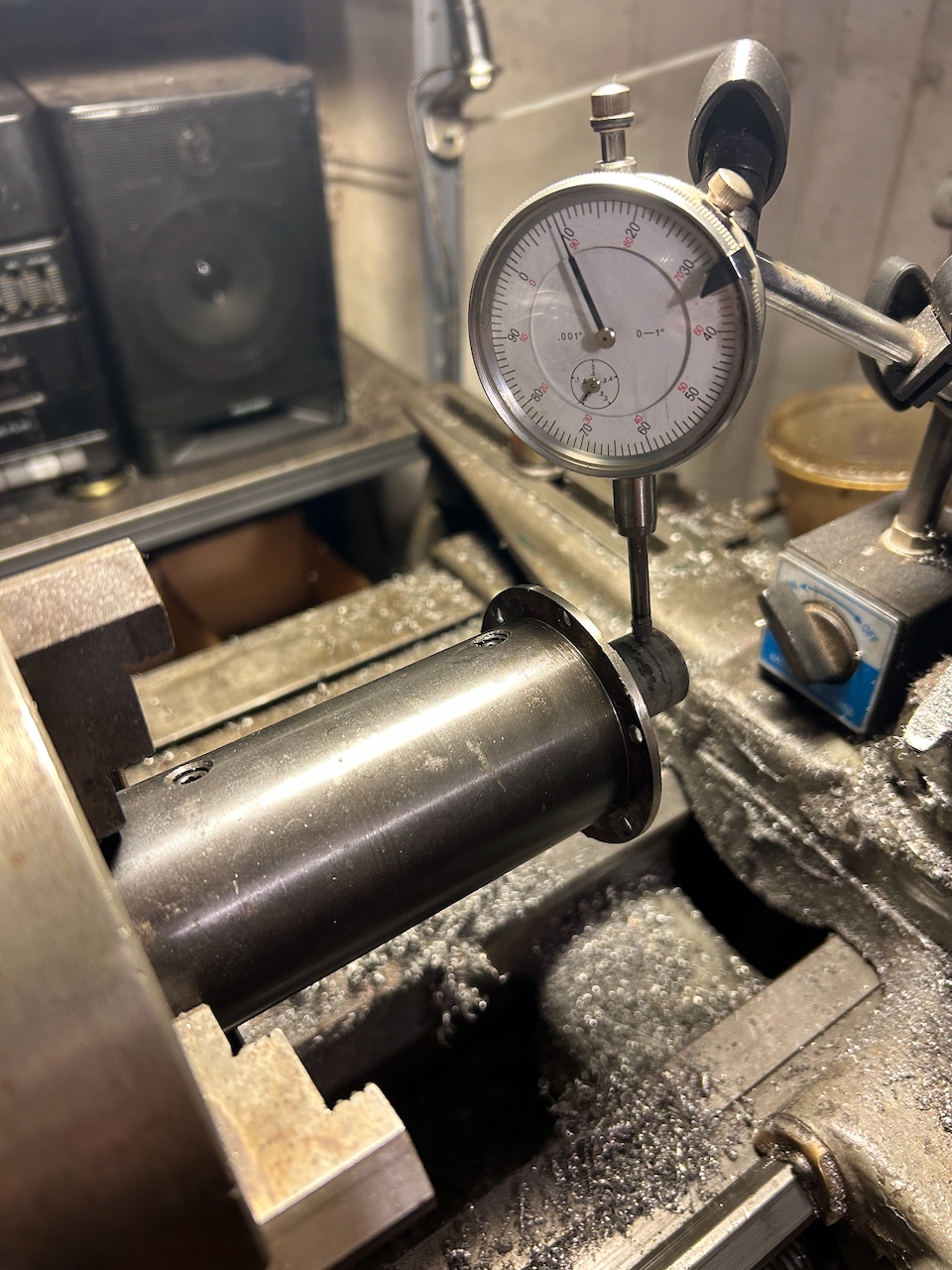

I've started the machining: I built this shaft coupler-to-clutch hub adapter with deliciously little runout (about .004").

Hope springs eternal.

-Alexander Pope, An Essay on Man

I have, on hand now, the replacement transmission (thank you Gabi B for putting me in touch with the seller, and thank s to the seller, Sarha M's husband - whose name escapes me right now but I'll remember it!), and a new motor from EVWest, a NetGain Micro 880 paired with a HyPer-Drive X125 controller. It's a 100V, 250A combo capable of delivering 10 kW continuously (about 13hp which compares favorably with the output of the original two-cylinder, two-stroke 399cc motor).

And this represents another weight-loss step: This motor is 40 lbs. Less still than the 65 lbs of the shunt-wound from the last two iterations, and way less than 185-lb forklift motor from the professor's conversion.

I will also be using lithium battery modules from an Ioniq 5 battery pack. I think it will be ten modules in two strings of five. More on that later.

Note that I opted not to use a Golden Motor set-up. Great price, and good specs for continuous power output (about the same as the NetGain), but the torque was a relatively light 24 ft-lb compared to the 98 ft-lb of the NetGain though still 20% better than the 20 ft-lb of the original internal-combustion motor (at 2200 rpm).

Not that I am not going to have to be careful about torque; I have to protect the little transmission! As mentioned above, I'm on my first replacement already.

I've started the machining: I built this shaft coupler-to-clutch hub adapter with deliciously little runout (about .004").

1-1/8" I.D. shaft coupler mated to

the clutch hub from the original clutch disk. Not yet

welded. One thing at a time. Note that it's in a

four-jaw chuck. My three-jaw has a runout of about

twenty thousandths.