Now it's spring 2025 and I am keen to

get the little red car back in shape for *this* year's

Microcar event!

Hope springs eternal.

I have, on hand now, the replacement transmission (thank you Gabi B for putting me in touch with the seller, and thanks to the seller, Amin S, who gave me a sqare deal and a new beginning!), and a new motor from EVWest, a NetGain Micro 880 paired with a HyPer-Drive X125 controller. It's a 100V, 250A combo capable of delivering 10 kW continuously (about 13hp which compares favorably with the output of the original two-cylinder, two-stroke 399cc motor).

And this represents another weight-loss step: This motor is 40 lbs. That is less than the 65 lbs of the shunt-wound from the last two iterations, and way less than 185-lb forklift motor from the professor's conversion.

I will also be using lithium battery modules from an Ioniq 5 battery pack. I will use eight modules in two strings of four, 100V nominal. More on that later.

Note that I opted not to use a Golden Motor set-up. Great price, and good specs for continuous power output (about the same as the NetGain), but the torque was a relatively light 24 ft-lb -- compared to the 98 ft-lb of the NetGain -- though still 20% better than the 20 ft-lb of the original internal-combustion motor (at 2200 rpm).

I am going to have to be careful about torque; I have to protect the little transmission! As mentioned above, I'm on my first replacement already.

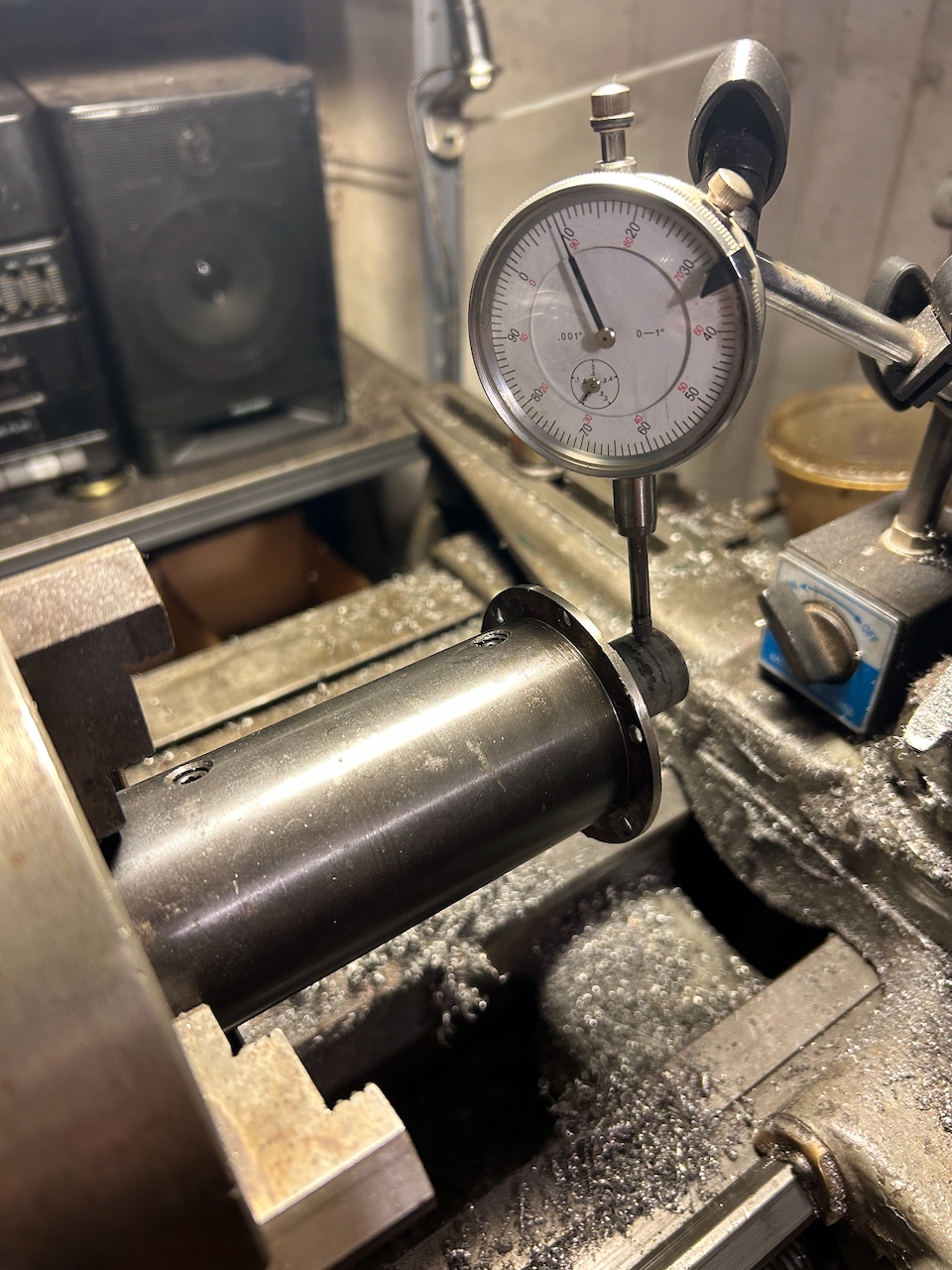

I've started the machining: I built this shaft coupler-to-clutch hub adapter with deliciously little runout (about .004").

Hope springs eternal.

-Alexander Pope, An Essay on Man

I have, on hand now, the replacement transmission (thank you Gabi B for putting me in touch with the seller, and thanks to the seller, Amin S, who gave me a sqare deal and a new beginning!), and a new motor from EVWest, a NetGain Micro 880 paired with a HyPer-Drive X125 controller. It's a 100V, 250A combo capable of delivering 10 kW continuously (about 13hp which compares favorably with the output of the original two-cylinder, two-stroke 399cc motor).

And this represents another weight-loss step: This motor is 40 lbs. That is less than the 65 lbs of the shunt-wound from the last two iterations, and way less than 185-lb forklift motor from the professor's conversion.

I will also be using lithium battery modules from an Ioniq 5 battery pack. I will use eight modules in two strings of four, 100V nominal. More on that later.

Note that I opted not to use a Golden Motor set-up. Great price, and good specs for continuous power output (about the same as the NetGain), but the torque was a relatively light 24 ft-lb -- compared to the 98 ft-lb of the NetGain -- though still 20% better than the 20 ft-lb of the original internal-combustion motor (at 2200 rpm).

I am going to have to be careful about torque; I have to protect the little transmission! As mentioned above, I'm on my first replacement already.

I've started the machining: I built this shaft coupler-to-clutch hub adapter with deliciously little runout (about .004").

1-1/8" I.D. shaft coupler mated to

the clutch hub from the original clutch disk. Not yet

welded. One thing at a time. Note that it's in a

four-jaw chuck. My three-jaw has a runout of about

twenty thousandths.

Big moment, 5/5/2025

Got that rear drive all put back together WITH the e-motor and its coupler. Looking pretty good.

At this point, the diff/transmission needs oil, and I need to attend to the speedo cable (still attached to the car) as it has a kink. But it's near ready to be reintegrated with the vehicle.

Shaft coupler is in the shadow

between the plates, lower center of image.

Update, 5/13/2025

The 400 is back on its own four wheels.

The transmission has some very fancy hypoid gear oil. (It's all about the health differential's pinion gear!)

On tippy toes, doing handbrake

connections, etc. Those things on the hood are BMS

harnesses from the Ioniq5 battery modules.

---

One of the ball-head nuts was stripped on the inside. Vanilla M12x1.5 thread, but with that sphere to keep the output shaft aligned between the facing parts of the giunto Boschi.

I tried to get one from Nicolas C. of France, who has saved me before, but it is too small a part to send by packet, and too small/cheap a part to do all the paperwork for! But here's the thing: Nicolas told me I don't need to worry about the ball-nut and that, in fact, the second gen doesn't even have them! I'm taking his word, and proceeding without.

One of the ball-head nuts was stripped on the inside. Vanilla M12x1.5 thread, but with that sphere to keep the output shaft aligned between the facing parts of the giunto Boschi.

I tried to get one from Nicolas C. of France, who has saved me before, but it is too small a part to send by packet, and too small/cheap a part to do all the paperwork for! But here's the thing: Nicolas told me I don't need to worry about the ball-nut and that, in fact, the second gen doesn't even have them! I'm taking his word, and proceeding without.

Left: the outbard star. Right: the

inboard star whose splines connect with the output shaft

of the tranny/diff. Top center: the ball-nut whose

threads are wrecked.

---

Here sits the 400 with the rear drive almost ready for wiring.

The drive assembly is all together but for bleeding brakes, connecting speedo cable, and connecting shifter linkage.

Here sits the 400 with the rear drive almost ready for wiring.

The drive assembly is all together but for bleeding brakes, connecting speedo cable, and connecting shifter linkage.

The 400 sitting on its own four

wheels for the first time in a year or so.

---

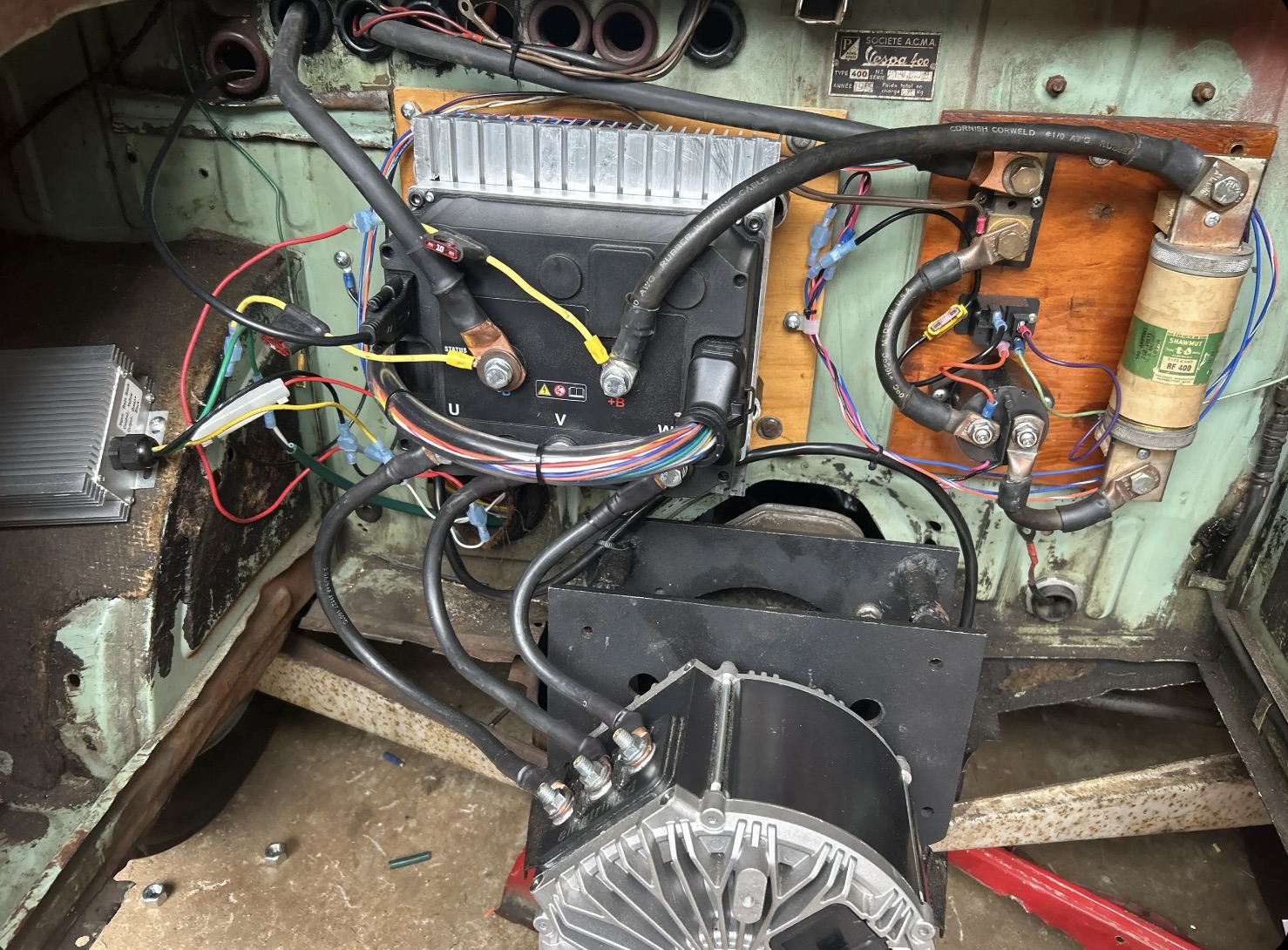

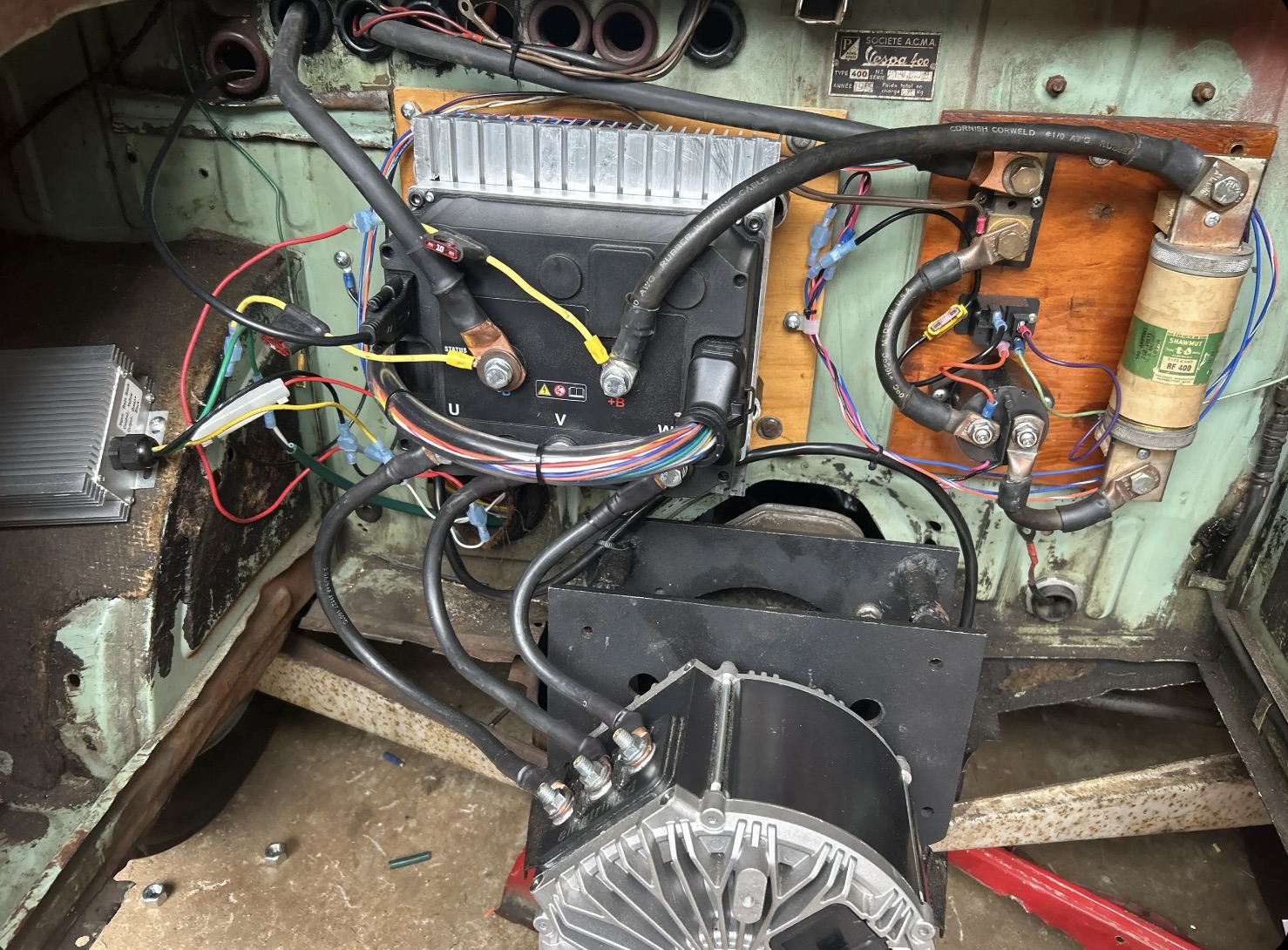

Wired up!

It has all come together: Connections, programming, DC-DC converter (thanks, eBay!) and cetera.

A note about the DC-DC converter: It's there to provide charging to the 12v accessory battery (lights, wipers (should they ever work again), horn, etc) since there's no alternator to keep the battery charged. This cheap DC-DC unit requires that the traction pack (the big battery that supplies the drive motor) and the car's 12v system share a ground. That is not usually done, even recommended against. (When I was first getting to know EVs I couldn't get my head around the idea! Now I wince at the notion of having any connection of the traction pack to anything but the controller.) Anyway, despite the unconventionality, I have them share a ground... but through a 10A fuse! I've already smoked one; a goof while wiring. Glad to have done it this way.

Anyway, the whole thing is ready for Gould's Microcar Event. It will make a showing, although I don't have much idea about range so I might not go on either of the days' rides as they are north of 60 miles each.

Far left: DC-DC converter provides 12v to accessory

battery. Right: the original conversion's fuse, built in

Newburyport MA. Wired up!

It has all come together: Connections, programming, DC-DC converter (thanks, eBay!) and cetera.

A note about the DC-DC converter: It's there to provide charging to the 12v accessory battery (lights, wipers (should they ever work again), horn, etc) since there's no alternator to keep the battery charged. This cheap DC-DC unit requires that the traction pack (the big battery that supplies the drive motor) and the car's 12v system share a ground. That is not usually done, even recommended against. (When I was first getting to know EVs I couldn't get my head around the idea! Now I wince at the notion of having any connection of the traction pack to anything but the controller.) Anyway, despite the unconventionality, I have them share a ground... but through a 10A fuse! I've already smoked one; a goof while wiring. Glad to have done it this way.

Anyway, the whole thing is ready for Gould's Microcar Event. It will make a showing, although I don't have much idea about range so I might not go on either of the days' rides as they are north of 60 miles each.